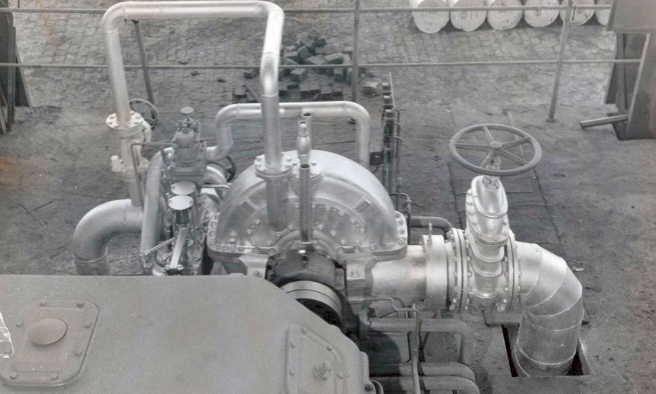

The MEGA-CO Series Multi-Stage Condensation Turbines have been developed for application mainly in power generator drives.

Pure condensation turbines are applied when the goal is to maximize the generation of electric energy with lower fuel consumption, without the need for steam to process. When a certain pressure/steam flow is required to meet the demand of some industrial process of client’s plant, a controlled or uncontrolled extraction block (bleed) can be added to the turbine.

The design of these turbines was developed in accordance with the API611/612 standards, including forced lubrication system, quick-action control and shut-off valves driven by hydraulic actuators, labyrinth-type steam and oil sealing and two-part housings; the high pressure part is in molten steel and the low pressure part in carbon steel plates, which allows greater flexibility of the position of steam output of the turbine, which can be downwards or upwards, sliding radial bearings and tilting pad type oscillating pellets.

The whole manufacturing process of the turbines and their components are executed following strict quality standards, accompanied by qualified inspectors, in order to guarantee maximum performance, meeting our clients’ expectations.

| Model | Speed (rpm) | Inlet Pressure (Bar a)** | Inlet Temperature (°C)** | Outlet Pressure (Bar a)** | Power (kW)** |

|---|---|---|---|---|---|

| MEGA300CO | 9000 | 52 | 480 | 0.10 | 1,500 |

| MEGA300ECO | 9000 | 52 | 480 | 0.10 | Upon consultation |

| MEGA400CO | 7000 | 52 | 480 | 0.10 | 3,000 |

| MEGA400ECO | 7000 | 52 | 480 | 0.10 | Upon consultation |

| MEGA500CO | 6500 | 52 | 480 | 0.10 | 6,000 |

| MEGA500ECO | 6500 | 52 | 480 | 0.10 | Upon consultation |

| MEGA600CO | 6000 | 48 | 480 | 0.10 | 10,000 |

| MEGA600ECO | 6000 | 48 | 480 | 0.10 | Upon consultation |

| MEGA10000CO | 6000 | 36 | 400 | 0.10 | 15,000 |

| MEGA10000ECO | 6000 | 36 | 400 | 0.10 | Upon consultation |

| MEGA15000CO | 6000 | 48 | 480 | 0.10 | 20,000 |

| MEGA15000ECO | 6000 | 48 | 480 | 0.10 | Upon consultation |

| MEGA25000CO | 5500 | 67 | 520 | 0.10 | 30,000 |

| MEGA25000ECO | 5500 | 67 | 520 | 0.10 | Upon consultation |

| MEGA35000CO | 5500 | 67 | 520 | 0.10 | 40,000 |

| MEGA35000ECO | 5500 | 67 | 520 | 0.10 | Upon consultation |