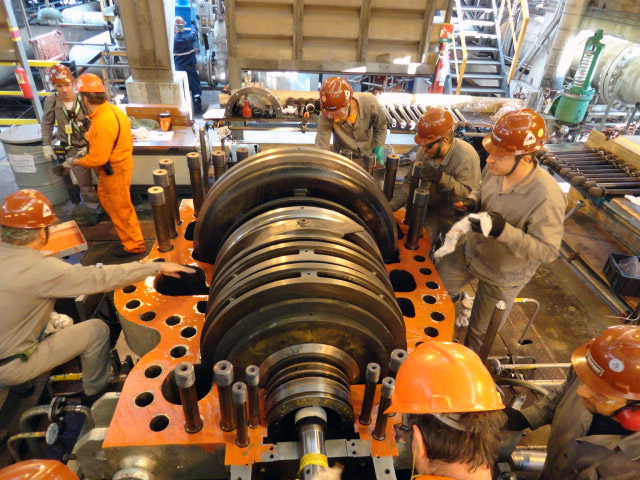

Through the know-how acquired during the 40 years of operation in the maintenance of steam turbines, we carry out maintenance of machines and shutdowns programmed in the most varied sectors of the industry.

The overhaul of machines can be carried out at the client’s premises by our external maintenance teams, which have representatives, supervisors, engineers, mechanics, instrumentalists, electricians, safety technicians and others, all specialized in equipment of the most different brands/models.

For more information, please contact our sales department.

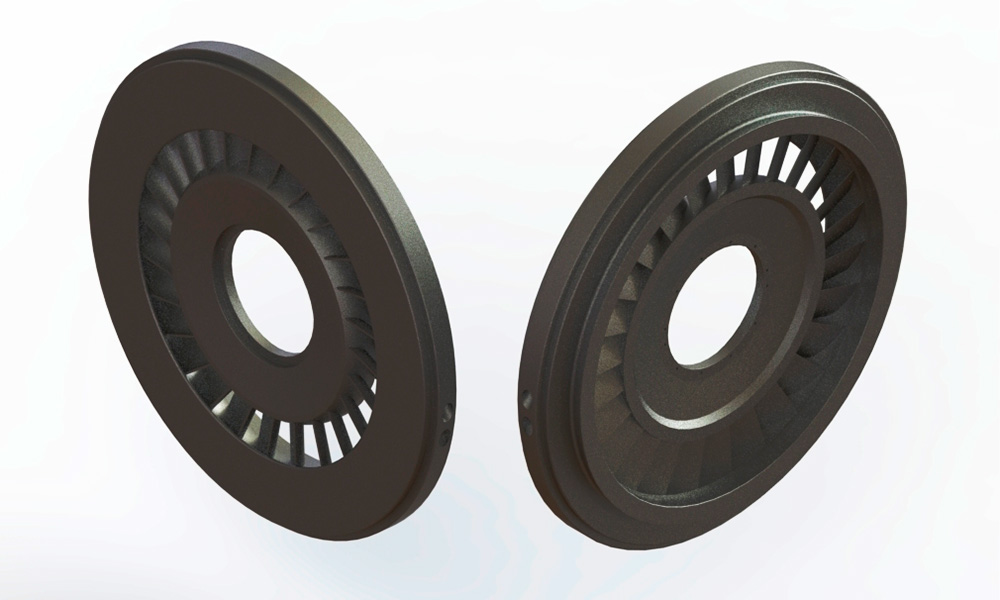

In order to solve existing problems or needs for improvement, we have high technology tools to evaluate and reverse engineer the most diverse components and parts of turbines and rotary machines.

Considering the complex geometry of parts manufactured for steam turbines and other rotating equipment, we offer state-of-the-art tools for 3D modeling and sizing, offering greater accuracy and quality for project design, Revere Engineering, as well as manufacturing processes.

For more information, please contact our sales department.

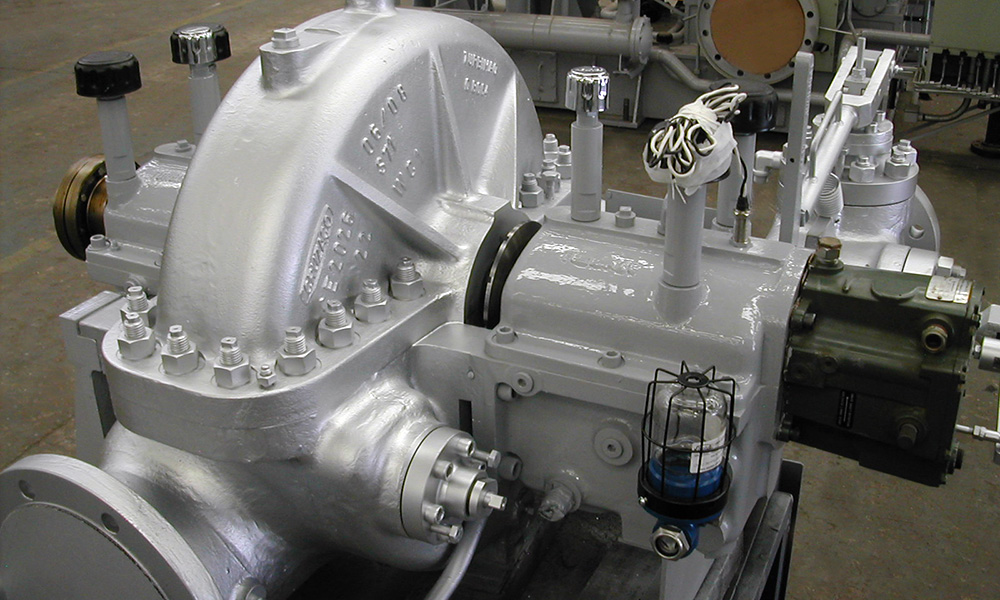

Considering the large number of installed machines and the recent technological development, Turbimaq is effectively performing the Retrofit/Modernization of equipment.

Retrofit/Modernization consists of upgrading control systems and safety of steam turbines, considered obsolete, by more modern systems, with innovative technologies, which gives the equipment greater reliability and operational safety.

Many of the installed turbines have mechanical speed regulator that acts on the control valves through levers. These turbines can be modernized by electronic control system, which acts on the control valves by means of servo hydraulic or pneumatic actuators, making the installation simpler and providing more precision and greater speed of response in the control of the turbine.

With regard to security systems, there are currently several technologies that allow incorporating redundancy into the system, which increases operational safety.

For more information, please contact our sales department.

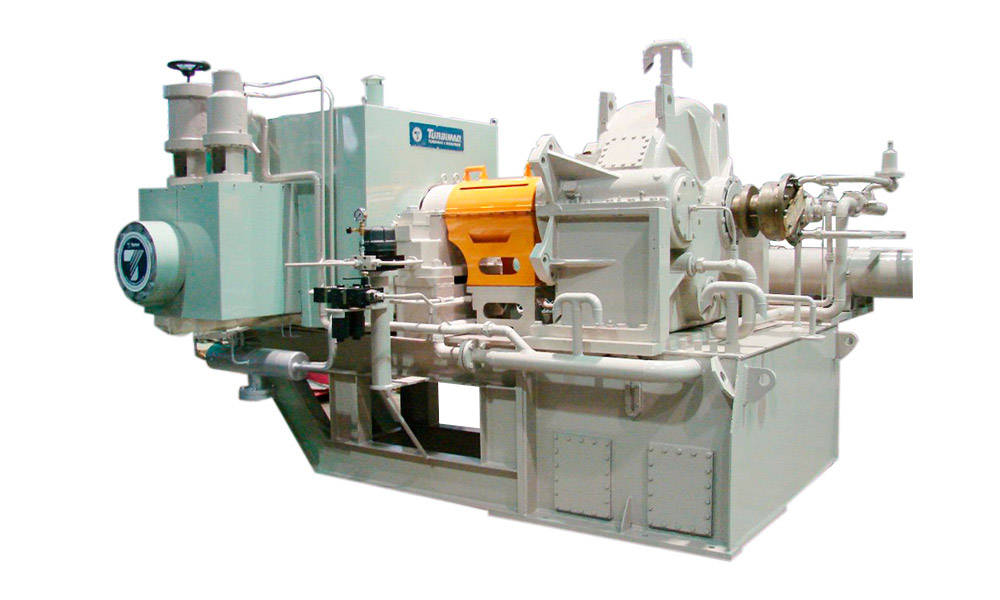

Turbimaq came on the market exclusively to meet the great demand for steam turbine maintenance, considering that the companies of the time were not able to meet the needs of a growing market.

Turbine maintenance consists of dismantling, cleaning, inspection, replacement of worn and damaged parts and components, balancing, geometric correction of frameworks, etc., always with the aim of restoring the turbine to its original condition of operation, and can be performed on turbines of all makes and models, whether domestic or imported.

For more information, please contact our sales department.

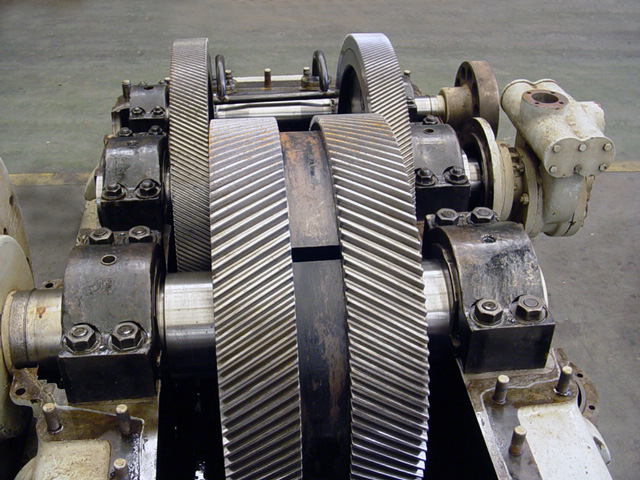

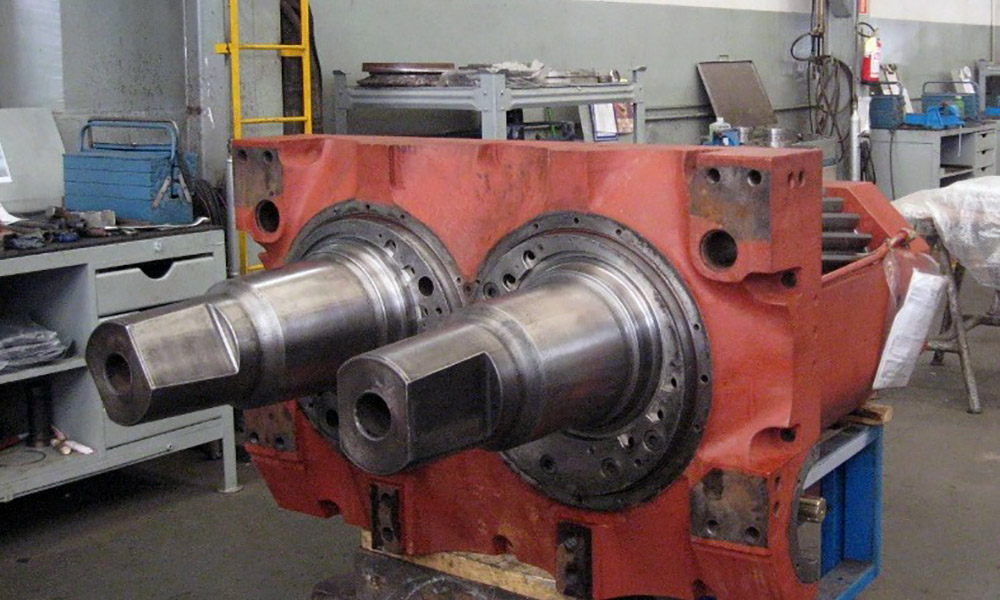

Our experience with steam turbine maintenance provides us with technical training to repair other rotary equipment, such as speed reducers.

Reducer maintenance consists of dismantling, cleaning, inspection, replacement of worn and damaged parts and components, balancing, geometric corrections of carcasses, etc., always with the aim of restoring the turbine to its original condition of operation, and can be performed on turbines of all makes and models, whether domestic or imported.

For more information, please contact our sales department.

Considering the continuous search of the market for cost reduction as well as increased operational efficiency, Turbimaq was one of the pioneers in the development of projects of transformation of Simple Turbines into Multi-Stage Turbines.

This service consists of the complete reengineering of the turbine, using tools that enable the development of vane with high performance profiles, resulting in a reduction in steam consumption of around 30%.

This solution provides for the complete or partial replacement of the turbine housing, complete replacement of the rotary assembly, complete replacement of the nozzle plates, among other parts.

For more information, please contact our sales department.

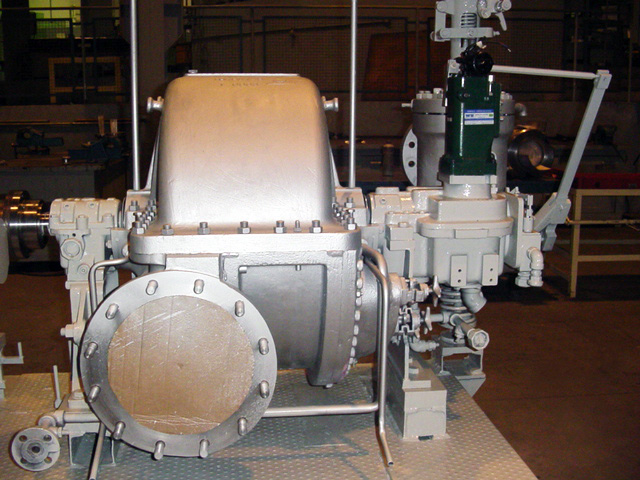

Our experience with steam turbine and speed reducer maintenance provides us with technical training to repair other rotary equipment, such as compressors, pumps, boosters, rotating shears and others.

The main purpose of the maintenance is to restore the equipment to its original condition of operation and it can be performed on rotary machines of different makes and models, whether domestic or imported.

For more information, please contact our sales department.

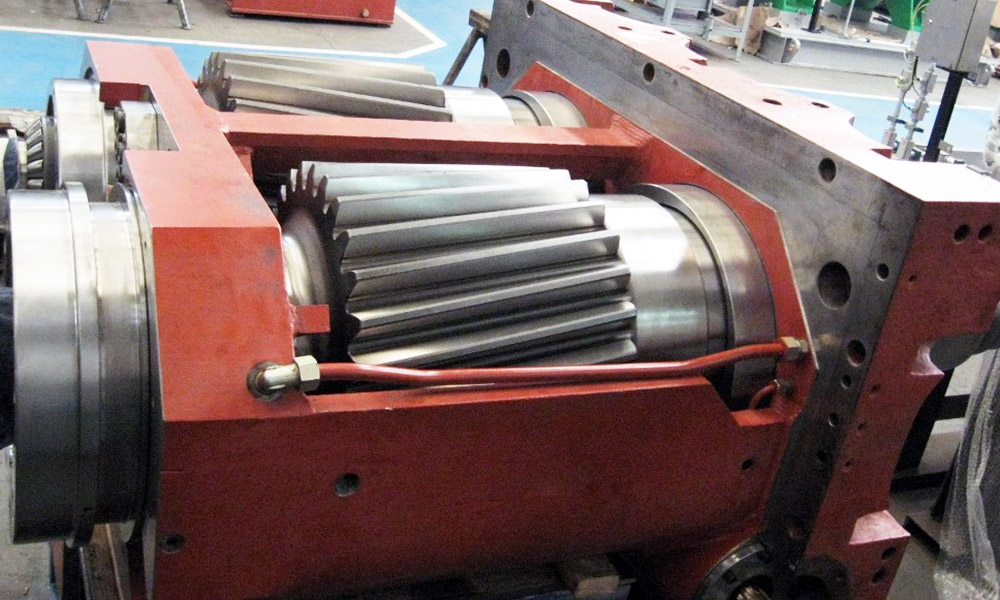

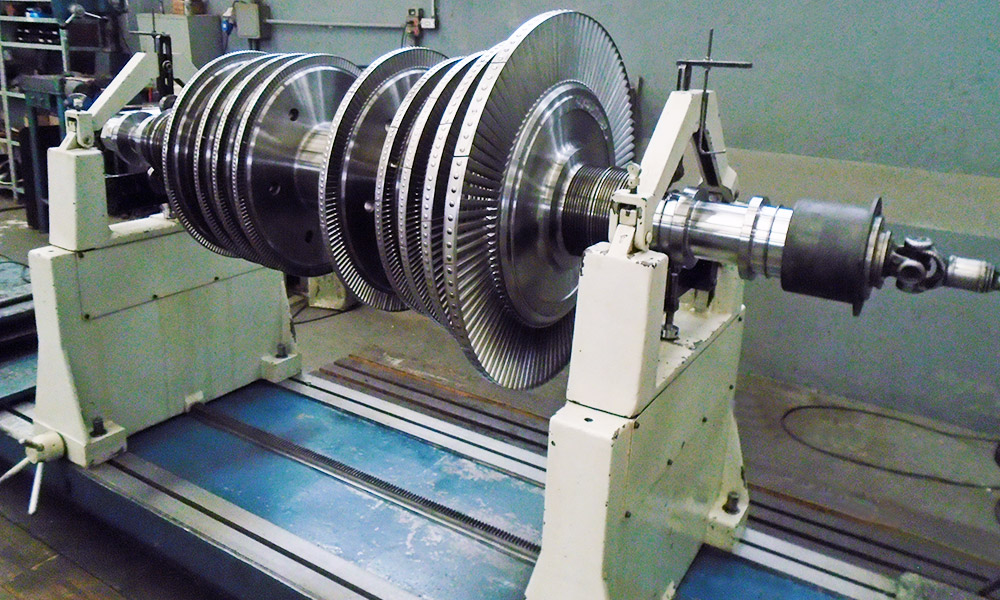

The rotating assembly is the main component of rotary machines, where balancing becomes a crucial item for the operation/performance of the equipment.

Our tradition in turbine maintenance gives us extensive experience to execute dynamic and static balances in accordance with applicable international standards.

For more information, please contact our sales department.

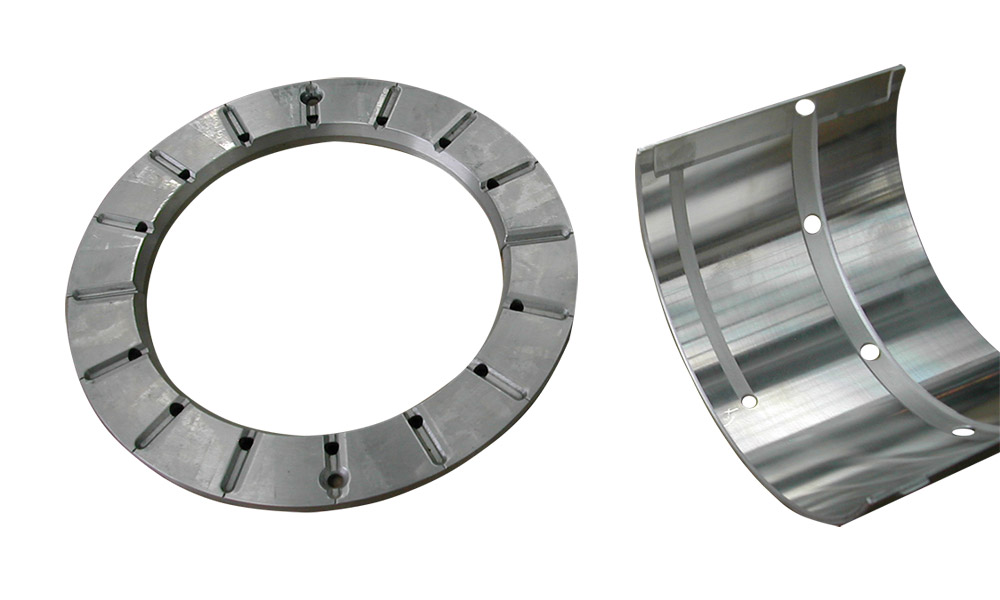

Bearings are components of great importance for the proper functioning of rotating equipment, since they give support to the rotating assembly of the machine.

Turbimaq began its activities exclusively by servicing equipment and recovering bearings. Thus, its 40 years of experience give it the know-how to design, manufacture and recover bearings of the most diverse sizes and shapes, including sliding, axial, tilting pad, lemon-shaped, quadrilobular, among others.

This experience with bearing recovery allows us to recover also other types of components with patent metal like for example shoes, crossheads, crossheads, among others.

Another modality that we offer is the manufacturing according to the client’s design or from reverse engineering of existing bearings.

For more information, please contact our sales department.

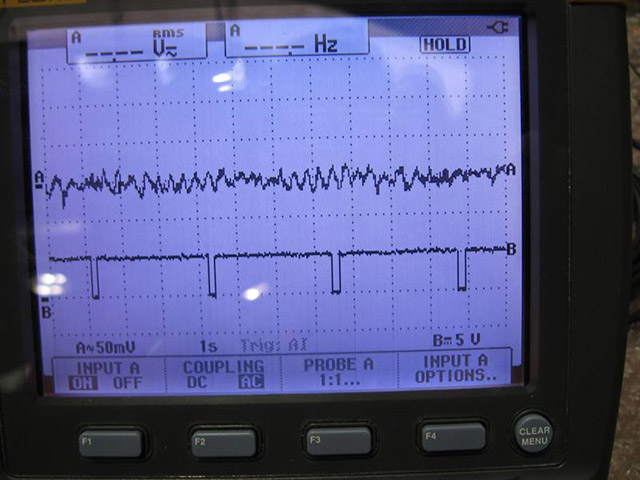

Due to the increasing demand for vibration monitoring in rotating equipment, Turbimaq has been equipped to run burnishing lanes on the axes where these systems are installed.

The burnishing service consists of the preparation of the tracks with a specified surface finishing (roughness) followed by the measurement of this roughness, guaranteeing the reading quality of the vibration sensors (Probes).

The above services can be performed on site.

For more information, please contact our sales department.

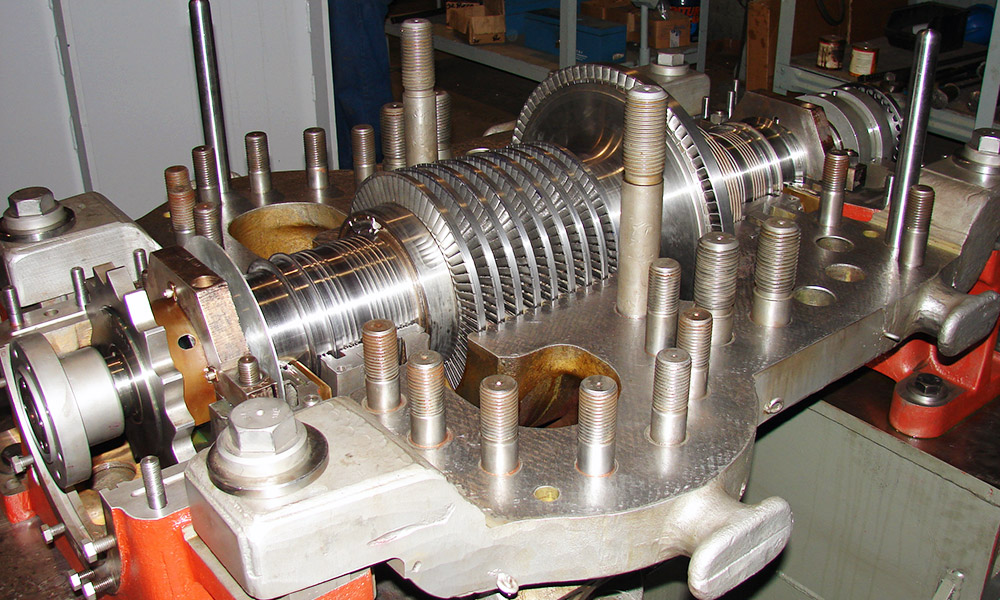

Aimed at a unique service to our clients, we installed in our industrial park a bench to carry out spinning tests with steam turbines, with the objective of delivering our equipment tested, thus reducing the need for adjustments during the commissioning in the field.

During the spinning test, several checks are made on the equipment, such as: bearing temperature, vibration, noise, safety system adjustment/testing, control system settings, among others.

This service can also be performed on existing equipment and/or from other manufacturers.

For more information, please contact our sales department.

Turbimaq has a specialized team to provide technical assistance services in steam turbines and rotary machines, with the objective of solving any emergency problems in our clients’ equipment.

Our specialists are available 24 hours a day for 7 days a week, for queries in Brazil and abroad.

Our contact telephone number is +386.27078900.

Aiming at increasing the operational availability of the machines of the industrial plant, the maintenance contracts are applied, in order to follow the equipment during the operation, monitoring its behavior over time, which allows the programming of small interventions to avoid unplanned and/or emergency shutdowns, which lead to increased maintenance costs.

For more information, please contact our sales department.